The importance of condition monitoring in industrial manufacturing

Condition monitoring is rapidly becoming a key component in modern industrial settings, thanks to the emergence of technologies that enable continuous, real-time monitoring of machinery. As companies strive to improve operational efficiency, reduce costs, and enhance workplace safety, integrating condition monitoring into their maintenance strategies offers significant benefits. Let’s explore Parker’s innovative IoT-based solutions and the transformation happening in the manufacturing sector as businesses shift towards predictive maintenance and asset optimization.

What is Condition Monitoring?

Condition monitoring refers to the process of continuously observing the health of machines, systems, or components to detect any signs of malfunction, wear, or failure. By tracking variables such as temperature, pressure, vibration, or oil quality, companies can predict potential failures and address them before they lead to unplanned downtime.

In the context of industrial equipment, condition monitoring ensures that machinery operates efficiently while minimizing the risk of breakdowns. This approach is central to predictive maintenance, a maintenance strategy that uses real-time data to predict when equipment failure might occur, allowing maintenance teams to perform repairs before the equipment fails entirely.

The Shift Towards Predictive Maintenance

Historically, industrial equipment maintenance followed two approaches: reactive and preventive. Reactive maintenance occurred after a machine failed, often resulting in costly downtime and lost production. Preventive maintenance, on the other hand, involved scheduled service checks regardless of the equipment’s actual condition, leading to unnecessary maintenance work and expenditure.

With the rise of the Industrial Internet of Things (IIoT), companies have adopted predictive maintenance strategies. This approach leverages sensors, cloud-based software, and analytics to monitor machine health in real time, predicting when failures might happen and allowing maintenance teams to intervene proactively. Predictive maintenance helps reduce unnecessary servicing, optimize spare parts usage, and minimize unplanned downtime.

Five Advantages of Condition Monitoring

The implementation of condition monitoring offers several benefits:

1. Minimizing Unplanned Downtime

One of the most significant advantages of condition monitoring is the reduction of unplanned downtime. By continuously monitoring machine health, potential issues can be detected early, allowing maintenance teams to address them before they lead to equipment failure. This proactive approach helps companies avoid costly shutdowns and maintain continuous production.

2. Protecting Other Machines

Machinery often operates as part of an interconnected system. When one machine malfunctions, it can affect others, leading to a chain reaction of failures. Condition monitoring enables the early detection of faults, preventing one machine’s failure from damaging others in the system.

3. Eliminating Unnecessary Maintenance

Traditional preventive maintenance schedules often result in over-servicing, as machines are serviced based on time intervals rather than actual need. With condition monitoring, maintenance is performed only when required, reducing unnecessary servicing and optimizing the use of maintenance resources.

4. Improving Maintenance Efficiency

By providing real-time data on machine health, condition monitoring enables maintenance teams to focus on the equipment that truly needs attention. This improves overall maintenance efficiency, as teams can prioritize their efforts and minimize time spent on routine checks.

5. Enhancing Workplace Safety

Faulty machines can pose significant safety risks to employees. Condition monitoring helps identify potential hazards early, ensuring that equipment is operating safely and reducing the likelihood of accidents in the workplace.

Parker’s Condition Monitoring Solutions

Parker Hannifin offers cutting-edge condition monitoring solutions designed to help businesses optimize their maintenance strategies and improve operational efficiency. Parker’s SensoNODE™ Gold sensors and Voice of the Machine™ software provide a comprehensive IoT-based condition monitoring system that continuously tracks machine health and delivers actionable insights to maintenance teams.

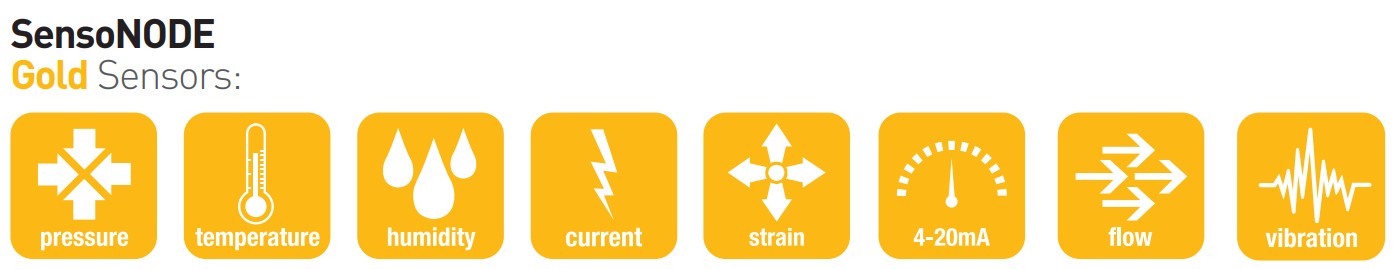

SensoNODE™ Gold Sensors

Parker’s SensoNODE™ Gold sensors are wireless, low-energy sensors designed to monitor critical variables such as pressure, temperature, and vibration. These sensors are easily integrated into existing machinery, making it simple for companies to start collecting data without significant modifications to their equipment.

SensoNODE™ sensors communicate wirelessly with Parker’s Voice of the Machine™ software, which aggregates the data and provides real-time insights into the condition of machinery. This allows maintenance teams to detect anomalies and take corrective action before a problem escalates.

Voice of the Machine™ Software

Voice of the Machine™ is Parker’s cloud-based software platform that collects, analyzes, and displays data from SensoNODE™ sensors. With a user-friendly interface and customizable dashboards, the software provides maintenance teams with a clear overview of machine health, making it easy to identify issues and track trends over time.

One of the key benefits of Parker’s Voice of the Machine™ software is its remote monitoring capabilities. Since the platform is web-based, maintenance teams can access machine data from anywhere at any time, allowing them to monitor equipment even when they are offsite.

The Power of IoT in Condition Monitoring

The integration of IoT technologies into condition monitoring systems has revolutionized the way companies approach maintenance and asset management. In traditional settings, maintenance teams relied on manual inspections or scheduled checks to assess machine health. With IoT-enabled sensors and cloud platforms, real-time data collection and analysis have become the norm, providing companies with a continuous stream of valuable insights.

IoT’s Role in Predictive Maintenance

IoT devices such as Parker’s SensoNODE™ sensors collect a wealth of data on machine performance, including real-time measurements of pressure, temperature, flow, and vibration. This data is sent to cloud-based platforms like Voice of the Machine™, where it is analyzed to identify patterns and predict when equipment failure might occur.

The predictive capabilities of IoT-based condition monitoring systems allow companies to move beyond reactive or preventive maintenance and adopt a more efficient predictive maintenance strategy. This not only reduces the risk of downtime but also helps companies optimize the lifespan of their equipment, ultimately leading to lower operational costs.

Connectivity and Data Analysis

The true value of IoT lies in its ability to connect machines, systems, and people across an entire factory or production line. Through wireless sensors and cloud-based platforms, IoT makes it possible for companies to collect data from every machine and subsystem, providing a holistic view of the health of their assets.

However, data alone is not enough. The challenge for many companies is to make sense of the vast amounts of information generated by IoT devices. This is where analytics and machine learning come into play. By analyzing historical data, companies can identify trends and pinpoint the root causes of machine failures, enabling them to optimize their maintenance strategies.

The Future of Condition Monitoring

As industries continue to embrace digital transformation, condition monitoring will play an increasingly important role in ensuring the efficiency, reliability, and safety of machinery. The integration of IoT devices, such as Parker’s SensoNODE™ sensors, and cloud-based platforms, like Voice of the Machine™, represents the future of maintenance and asset management.

The shift towards predictive maintenance, driven by IoT and condition monitoring, offers companies the opportunity to optimize their operations, reduce costs, and stay competitive in an increasingly connected world. By embracing these technologies, companies can not only improve the performance of their equipment but also create a safer and more efficient workplace for their employees.

Conclusion

Condition monitoring is transforming the way companies manage their assets and maintenance strategies. By leveraging IoT-enabled sensors and cloud-based platforms, businesses can monitor the health of their machines in real-time, predict failures before they happen, and optimize their maintenance efforts. Parker’s innovative SensoNODE™ Gold sensors and Voice of the Machine™ software provide a powerful solution for companies looking to implement predictive maintenance and improve operational efficiency. As the digital transformation continues, condition monitoring will become an indispensable tool for companies looking to stay ahead of the curve in a competitive and ever-evolving industrial landscape.

At A&C Engineering, a Premier Distributor of Parker, you can purchase high-quality sensors for your condition monitoring and IoT needs. Our range includes Parker’s SensoNODE™ Gold sensors, designed to ensure seamless real-time monitoring of your machinery. Whether you’re looking to optimize maintenance or enhance operational efficiency, our team is here to assist you. Feel free to contact us anytime for more information or inquiries regarding our products and services.