The Hydrogen Journey

Source: blog.parker.com

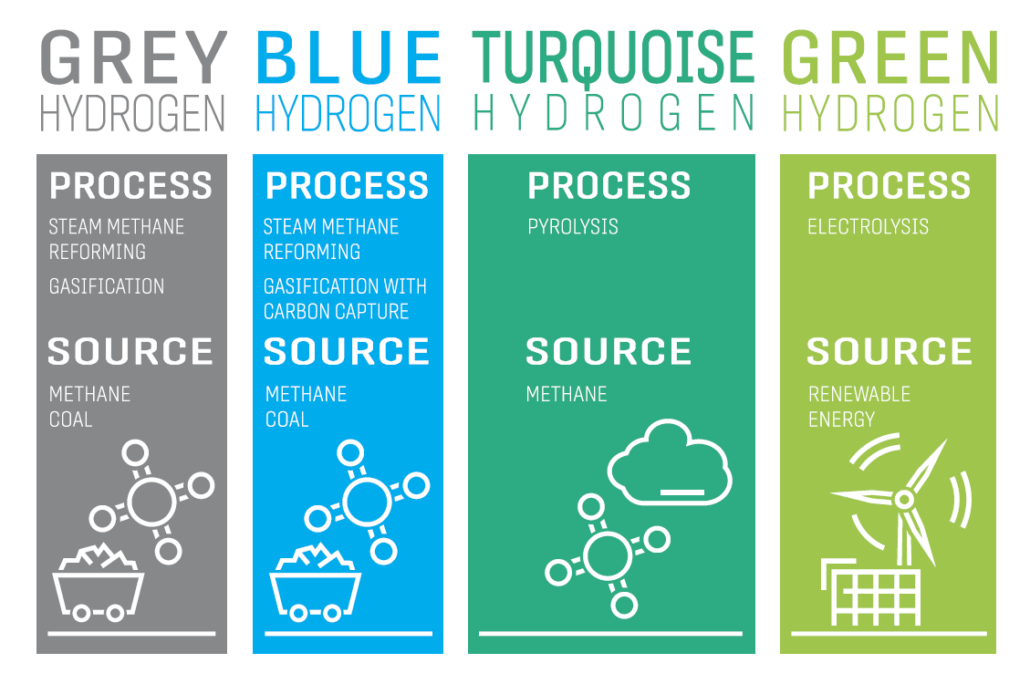

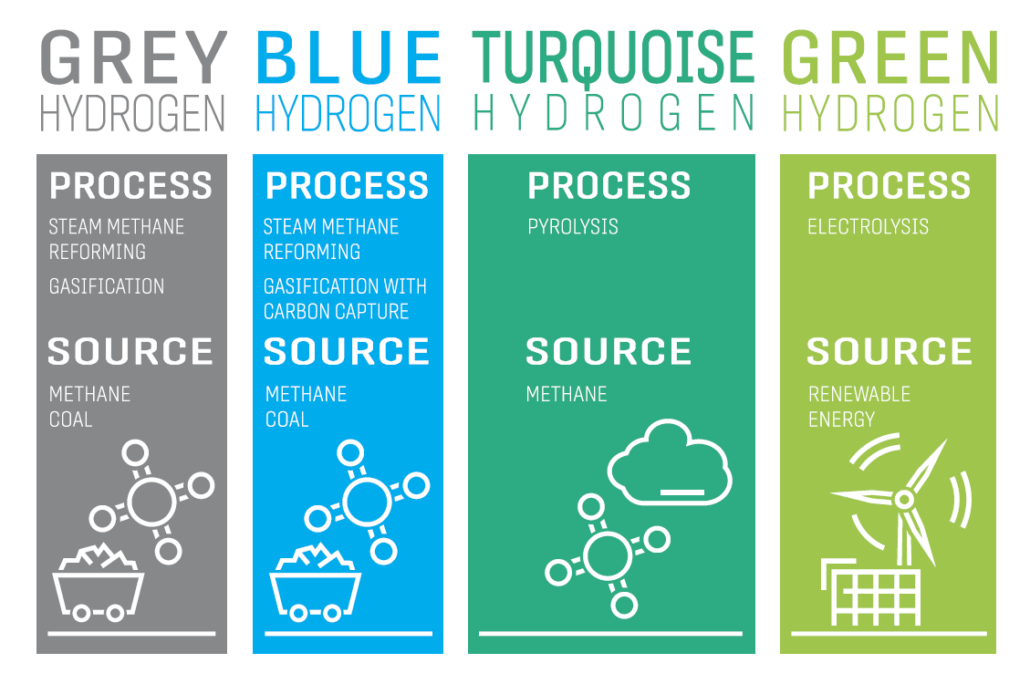

Hydrogen production methods vary significantly, each with a different carbon footprint. These include:

– Grey Hydrogen: Derived from steam methane reforming.

– Blue Hydrogen: Grey hydrogen with carbon capture.

– Green Hydrogen: Produced via electrolysis using renewable energy.

– Turquoise, Pink, Purple, and Yellow Hydrogen: Produced using various other methods like methane pyrolysis and nuclear energy.

Transporting hydrogen, especially in gaseous form, requires managing pressures that can exceed 1,000 bar (14,500 psi). Liquid hydrogen, transported at -252.87°C (-423.17°F), demands super-insulated cryogenic tanks.

Addressing Risks and Considerations

Leak Prevention

The primary concern with hydrogen systems is preventing leaks due to hydrogen’s small molecular size and high flammability. Establishing an acceptable leak rate is essential. Parker’s Hi-Pro Series Ball Valves and H Series Needle Valves are designed to meet various tightness classes under ISO 15848-1:2015, ensuring minimal fugitive emissions.

Material Selection

Hydrogen embrittlement, where hydrogen molecules weaken metals, poses a significant risk. Parker recommends using 316/316L stainless steel for its resistance to hydrogen damage, supported by comprehensive material traceability and adherence to standards like ASME B31.3.

Pressure Management

Choosing the right tubing size and material based on operating pressure is crucial. Parker provides detailed tubing charts, ensuring that selections meet safety factors of 4:1 or 2:1 depending on the application. For example, their Autoclave Engineers cone and thread fittings are suitable for high-pressure environments.

Training and Standardization

Proper installation and maintenance require professional training. Parker emphasizes the importance of using standardized components to simplify installation, reduce errors, and lower costs.

Key Products for Hydrogen Systems

Parker offers a range of products specifically designed for hydrogen applications:

– Hi-Pro Series Ball Valves: Available in Class A, B, and C fugitive emission options.

– H Series Needle Valves: High-integrity sealing with reduced leak paths.

– Phastite® Non-Weld Push-Fit Connectors: Suitable for pressures up to 1,550 bar (22,500 psi).

These products are designed to ensure reliability, safety, and efficiency in hydrogen systems, addressing the unique challenges posed by hydrogen’s properties.

Conclusion

Parker valves are integral components in numerous industries, providing reliable, efficient, and precise control of fluid dynamics. Whether it’s in construction, aerospace, manufacturing, or medical equipment, Parker’s extensive range of valve products ensures that every application is met with the highest standards of performance and safety.

All of these high-quality Parker valve products are available at A&C Engineering, your trusted source for engineered solutions. Visit A&C Engineering today to find the perfect Parker valve for your specific needs. If you have any questions, our knowledgeable team is here to help. Contact us for more information and expert assistance.

Click Here to read more about optimizing small bore tubing systems for hydrogen applications