ATEX Valves from Parker: Ensuring Safety in Hazardous Environments

In industries where hazardous atmospheres may be present, such as oil and gas, chemical processing, and mining, the risk of explosions or fire is high. This is where ATEX-certified products come into play. These valves ensure safety while maintaining optimal performance in environments where flammable gases, vapors, or dusts are a risk.

What is ATEX?

ATEX stands for ATmosphères EXplosibles, which is a European Union directive that outlines essential safety requirements for products used in explosive atmospheres. ATEX-certified products are thoroughly tested to ensure that they comply with the stringent requirements of the directive. This certification ensures that the products can be safely used in areas where flammable materials are present. It’s important to note that the ATEX directive doesn’t just apply to industrial processes involving gas and vapor hazards. It also covers environments where dust can ignite, such as grain mills, wood processing plants, and food manufacturing.

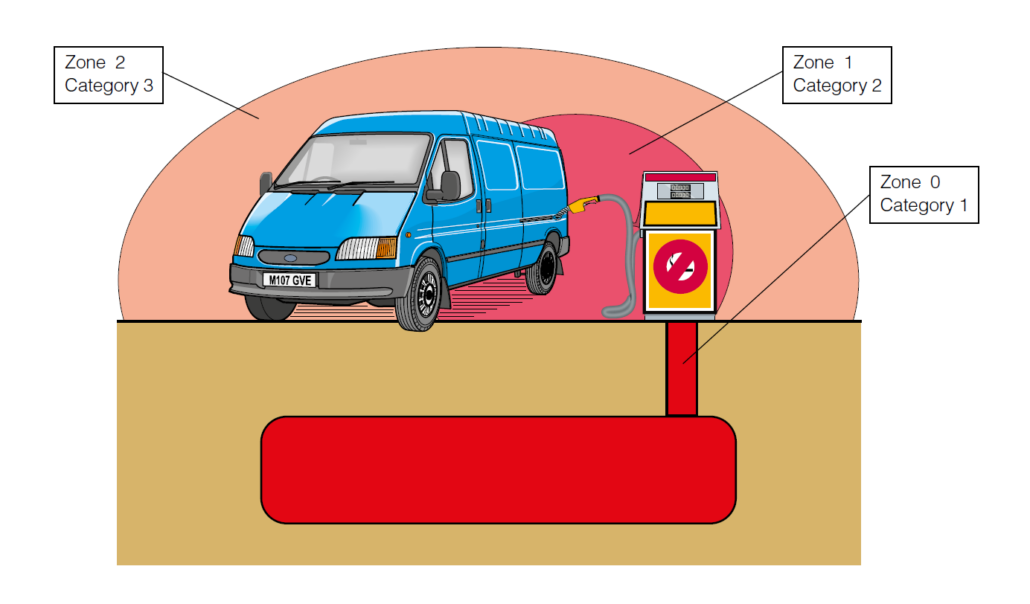

Hazardous areas are classified into zones based on the likelihood and duration of the presence of explosive atmospheres, which could be caused by gases, vapors, or dust.

Gas/Vapor Zones:

– Zone 0: Explosive atmosphere (from gas or vapor) is present continuously or for long periods (more than 1,000 hours/year).

– Zone 1: Explosive atmosphere is likely to occur occasionally (between 10 and 1,000 hours/year).

– Zone 2: Explosive atmosphere is not likely to occur during normal operations, and if it does, it will only exist for a short period (less than 10 hours/year).

Dust Zones:

– Zone 20: Explosive atmosphere (from combustible dust) is present continuously or for long periods.

– Zone 21: Explosive atmosphere may occur occasionally due to dust.

– Zone 22: Explosive atmosphere is unlikely during normal operations but may occur briefly.

Source: Parker PDE2584TCUK

The Importance of ATEX Compliance

When dealing with explosive environments, it is critical that the equipment and components used are designed to minimize risks. The consequences of not complying with ATEX requirements can be catastrophic, both in terms of human lives and financial loss. Equipment that isn’t compliant with ATEX could malfunction, causing fires, explosions, or even structural damage. Non-compliance can lead to legal action, fines, and significant downtime for businesses.

Parker’s Commitment to ATEX Standards

ATEX-certified valves from Parker are built to meet the highest safety standards and to operate efficiently in the most challenging conditions. With decades of experience and a reputation for reliability, Parker ensures that the ATEX valves are meticulously designed and tested to meet all relevant ATEX standards.

In addition to the ATEX certification, Parker valves also comply with various other international standards and certifications, making them versatile for use not only in Europe but also across other regions that require explosion-proof equipment.

Understanding Parker’s ATEX Valves

Parker ATEX-certified valves are specifically designed to handle operations in potentially explosive atmospheres. They are used in various applications where safety is crucial, such as controlling the flow of gases or liquids in chemical plants, oil and gas refineries, and other environments prone to hazardous conditions.

1. Types of ATEX Valves

Parker offers a wide range of ATEX valves for different industrial needs. Some of the most commonly used types include:

– Solenoid Valves: These electrically-operated valves are ideal for controlling the flow of fluids or gases. Parker’s ATEX-certified solenoid valves are designed to prevent sparking, even in environments where flammable gases or dust are present.

– Ball Valves: Ball valves are versatile and can be used for both on-off control and modulating services. Parker’s ATEX ball valves are constructed to prevent ignition from potential sparks, making them ideal for handling flammable liquids and gases.

– Butterfly Valves: These are primarily used for throttling purposes. ATEX-certified butterfly valves from Parker are lightweight yet robust, offering a safe and efficient way to regulate the flow of materials in potentially hazardous environments.

– Pressure Relief Valves: These valves are crucial for safety, as they help prevent overpressure conditions that could lead to an explosion. Parker’s ATEX-certified pressure relief valves are designed to automatically relieve pressure in a controlled manner, ensuring that hazardous conditions are mitigated before they become dangerous.

2. Key Features of Parker’s ATEX Valves

What makes Parker ATEX-certified valves stand out is their focus on both safety and performance. Here are some of the key features that highlight the excellence of Parker’s ATEX valves:

– Ignition-Proof Design: The most critical feature of any ATEX-certified valve is that it must not be capable of igniting the hazardous atmosphere. Parker’s valves are designed with explosion-proof housings and other safeguards that eliminate the risk of sparking.

– Corrosion Resistance: In many industrial applications, the materials being transported or controlled are highly corrosive. Parker’s ATEX valves are made from corrosion-resistant materials to ensure long-term reliability even in the harshest environments.

– Temperature and Pressure Tolerance: These valves are designed to operate in extreme temperatures and pressures, which is essential for applications in industries like oil and gas, where conditions can be extreme. Parker’s ATEX valves are tested for their durability under such conditions.

– Easy Installation and Maintenance: Parker’s ATEX valves are designed for easy installation and maintenance. This not only reduces the risk of operator error but also minimizes downtime, which is critical in industries where any disruption can result in significant financial losses.

3. Customization Options

Parker also offers customizable ATEX valve solutions. This is particularly beneficial for businesses with unique requirements that go beyond the standard offerings. Whether it’s a specific pressure range, material choice, or valve size, Parker can tailor its ATEX valves to meet the precise needs of its customers.

How to Choose the Right ATEX Valve for Your Application

Choosing the right ATEX valve can be a complex process, given the wide variety of applications and environments where these valves are used. Here are some key factors to consider when selecting the appropriate valve for your needs:

- Type of Hazardous Atmosphere: The first step in choosing the right ATEX valve is understanding the specific hazardous environment where it will be used. This could include gas, vapor, or dust. Different types of atmospheres may require different types of valves and certifications.

- Pressure and Temperature Requirements: Ensure that the valve can handle the specific pressures and temperatures it will be exposed to. Parker offers valves that can operate in extreme conditions, but it’s important to select the one that matches your operational needs.

- Application: The type of material being controlled. Whether it’s a gas, liquid, or granular material, will also determine the best valve choice. For example, a solenoid valve might be better suited for fast-acting control, while a ball valve could be more appropriate for on-off applications.

- Size and Flow Capacity: Depending on your system’s requirements, you’ll need to choose a valve with the right flow capacity. Undersized or oversized valves can lead to inefficiency and operational issues.

- Customization: Parker’s customizable ATEX valves can be designed to match your exact requirements.

At A&C Engineering, we understand that choosing the right valve can be difficult. Feel free to contact us if you need any help with choosing the right ATEX valve. Our team is ready to help you!

Conclusion: Why Parker’s ATEX Valves are a Trusted Choice

Parker ATEX-certified valves not only meet the stringent requirements of the ATEX directive but also offer industry-leading reliability and performance. With a range of valve types, customization options, and a focus on safety, Parker ensures that their products are not just compliant, but are also capable of handling the most demanding applications.

By choosing Parker’s ATEX-certified valves, you are investing in both safety and efficiency. This ensures that your operations run smoothly without compromising the well-being of your employees or your business.

For more information about ATEX valves and how they can be implemented in your operations, feel free to contact us at A&C Engineering. Our team of experts is ready to help you find the best solution for your specific needs.