Parker AC20F Series controller: Makes hydraulic machines smarter, faster and more efficient

Why modern hydraulics need a new kind of pump controller

Industrial hydraulics still delivers unbeatable force density, but traditional fixed-speed pump systems waste energy, create heat, and raise noise levels. Variable-speed drive-controlled pump (DCP) systems solve most of these problems, yet they only reach their full potential when the frequency inverter truly understands both electric motor dynamics and hydraulic process demands. That is exactly the gap the Parker AC20F Series Controller was designed to fill.

The Parker AC20F Series Controller

The AC20F is a compact, cost-effective AC drive that controls induction or permanent-magnet motors from 1.5 kW up to 180 kW in heavy-duty hydraulic applications. Despite the slim footprint, the controller packs system-class capabilities such as sensorless vector control, encoder feedback, Safe Torque Off (STO), on-board Ethernet and field-swappable option cards.

At its heart, Parker tuned the firmware for hydraulics. Ready-made algorithms handle flow control, pressure control, automatic P/Q switching, electronic load control (eLCP) and accumulator charging without external PLC code. These native functions turn the AC20F into a “hydraulic brain“ rather than a generic VFD.

Download the Parker MSG11-3352UK catalog

Five benefits of the AC20F

- Modular design: Main unit plus plug-in IO, feedback and network cards let you buy exactly what you need today and expand tomorrow.

- Extensive functionality: Built-in hydraulic modes remove the cost and risk of custom PLC code.

- Easy commissioning: Free DSE Lite software, an integrated web server and a graphical keypad slash start-up time.

- Comfortable programming: Drag-and-drop function blocks, live trending, Ethernet firmware updates.

- Condition monitoring: Oil temperature, level and filter status alarms protect the power unit. No extra sensors or PLC logic required.

A closer look at the key features

1. Integrated hydraulic intelligence

- Flow-controlled speed regulation keeps volumetric flow proportional to cylinder velocity for faster cycles.

- Pressure control with 150 % / 60 s overload delivers the high force peaks demanded by presses and die-casting machines.

- Automatic P/Q switching optimises energy use by lowering motor speed during holding or metering phases.

- eLCP (electronic Load Control) stabilises load-sensing systems and reduces oscillations.

2. Power and performance

- 1.5-180 kW power range in nine frame sizes supports everything from small test rigs to large injection moulders.

- Output frequency up to 590 Hz and selectable switching frequencies (up to 10 kHz) give designers freedom to run asynchronous or PMAC motors at the ideal operating point.

- 150 % overload for 60 s ensures critical axes never stall during high-pressure segments of the cycle.

3. Safety and compliance

- Standard Safe Torque Off (STO, SIL 3/PLe) cuts power to the motor within milliseconds, simplifying compliance with ISO 13849 and IEC 62061.

- IP20 construction and C3-class EMC filter options support cabinet mounting in harsh industrial environments.

4. Open connectivity

Whether your plant runs PROFINET, EtherCAT, Ethernet/IP, CANopen, PROFIBUS or Modbus RTU, a matching option card clicks into slot 1 or 2 of the AC20F. Two cards can be used simultaneously for flexible topologies such as fieldbus + encoder feedback.

5. Field-swappable I/O expansion

The 2004-IO-00 GPIO card adds analogue and digital channels for closed-loop valve control, while the 2004-EN-00 encoder card enables full closed-loop vector mode for maximum efficiency at low speeds.

Download the Parker AC20F infographic to learn more about the benefits of the drive controller.

Fast, frustration-free commissioning

Traditional hydraulic retrofits often stall when electrical engineers hand a drive to hydraulic specialists, or vice versa. Parker eliminates the gap with two tools:

- DSE Lite: A free, Ethernet-based configuration suite that uses block diagrams instead of cryptic parameter trees. Upload-once templates let OEMs clone settings across multiple machines in seconds.

- Integrated web server: Open a browser, type the drive’s IP address, and tweak parameters, back up firmware, or trigger diagnostics remotely. In plain language, no software install required.

Together, they cut commissioning time by up to 70 % compared with generic drives that require external PLC logic.

Built-in condition monitoring

Unplanned downtime is a profit killer. The AC20F constantly logs and supervises:

- Oil temperature: warns before viscosity drops outside spec.

- Oil level: signals leaks or aeration risk.

- Filter condition: prevents pressure spikes and cavitation.

Due to this, it is possible to push alerts straight to the SCADA layer across any supported fieldbus. No extra PLC code, wiring or licenses.

Energy efficiency you can measure

Pair the AC20F with Parker T7 vane pumps or PVplus axial piston pumps and the drive continuously adjusts motor speed so the pump only produces the flow and pressure actually required by the machine cycle. Field data show energy savings of 30-70 % compared with fixed-displacement units, plus dramatically lower heat rejection, often eliminating the need for an oil cooler.

Applications of the Parker AC20F

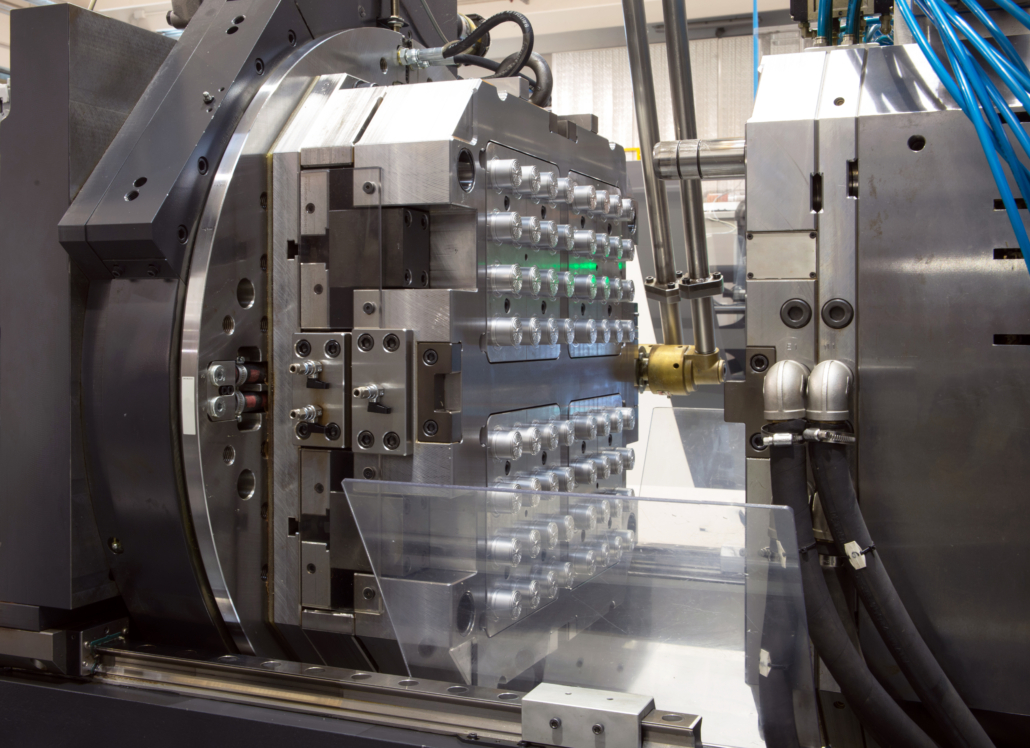

- Hydraulic presses: high-force forming, thermoforming, metal stamping.

- Die-casting machines: rapid pressure build-up and precise shot control.

- Injection moulding: repeatable plasticising, holding and back-pressure profiles.

- Test rigs: variable pressure/flow profiles without throttling losses.

- Retrofit energy upgrades: replace a starter-driven pump with an AC20F-controlled DCP to hit ISO 50001 targets fast.

Future-proof your machine

Because Parker engineers keep the hydraulic algorithms in the firmware, enhancements such as AI-based predictive maintenance or new fieldbus profiles can be delivered as Ethernet firmware updates, no hardware swap required.

Conclusion

The Parker AC20F Series Controller blends the deep torque control of a modern vector drive with ready-made hydraulic expertise. Its modular hardware, open communications and intuitive software turn what used to be a complex, multi-component project into a single-box solution that slashes energy use, accelerates commissioning and extends machine life.

If you are designing or retrofitting hydraulic presses, die-casting cells or injection moulders, the AC20F should be at the top of your shortlist.

For inquiries, questions, or more information about the Parker AC20F Series Controller, feel free to contact us. We are ready to help you find the best solution for your application.